PLC & Industrial PC Enclosures

Sheet metal housings precisely machined for PLCs, IPCs, and I/O modules — complete with cable entries, knockout zones, and mounting patterns tailored to your design.

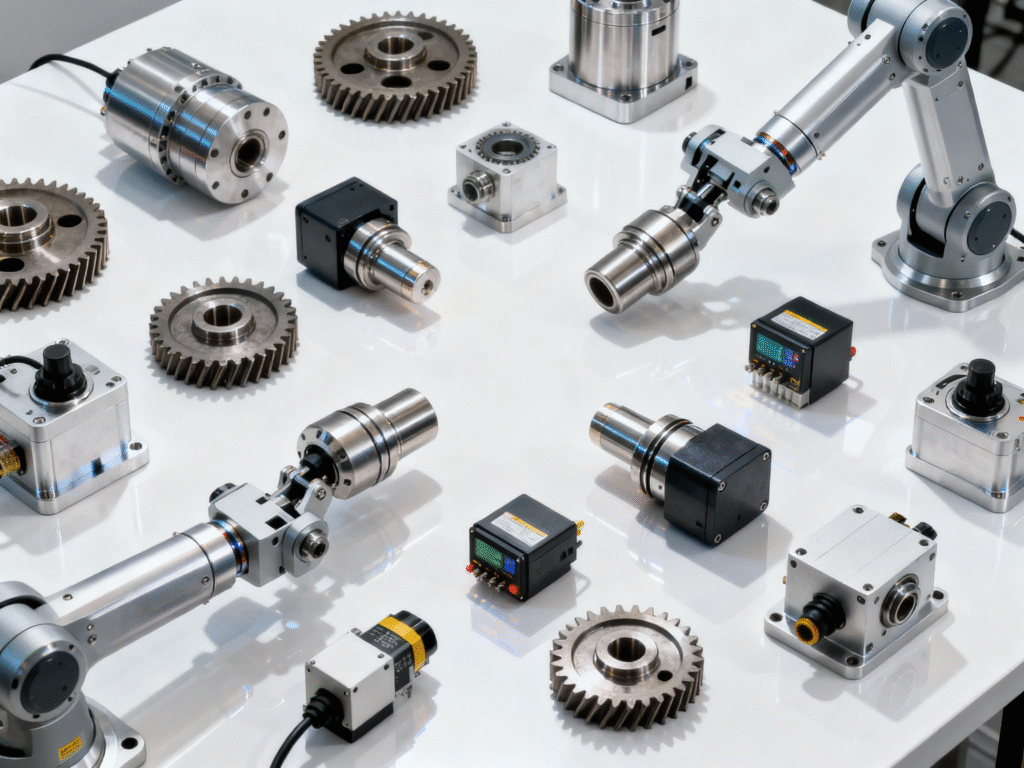

We engineer robust custom enclosures, structural components, and precision panels for next-generation automation systems — from ASRS and robotics to IoT terminals. Our solutions support intelligent operation while minimizing hardware-related downtime.

In modern industrial environments, automation systems face relentless mechanical and electrical stress — from vibration and EMI to thermal buildup. When components like PLC enclosures or control modules fail due to heat or poor shielding, costly downtime follows.

At Cherying, we solve these problems through precision CNC machining, EMI-conscious design, and exacting quality standards. Every bracket, panel, and enclosure is built to ±0.01mm tolerances and optimized for strength, thermal dissipation, and EMC protection.

We design and manufacture high-performance enclosures, brackets, and thermal elements to keep your PLCs, drives, and control modules protected, organized, and efficient — from small DIN‑rail parts to complete panel assemblies.

Sheet metal housings precisely machined for PLCs, IPCs, and I/O modules — complete with cable entries, knockout zones, and mounting patterns tailored to your design.

Materials: 5052 / 6061 aluminum, cold‑rolled steel, stainless steel.

Front panels with precision cut‑outs for HMIs, pushbuttons, and key switches — allowing clean layouts, intuitive labels, and fast control cabinet integration.

Finishes: brushing, anodizing, powder coating, laser engraving, silkscreen.

CNC‑cut structural plates that hold terminals, relays, and power supplies securely in place — simplifying panel wiring and reducing maintenance overhead.

Tolerances: ±0.01 mm for slots, hole patterns, and grounding points.

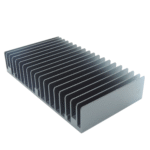

Custom-designed heatsinks, shield plates, and covers that ensure thermal regulation and EMI protection for drives, motion controllers, and power modules.

Engineered for consistent performance in harsh environments.

Whether for rapid prototyping or stable long-term production, Chenying delivers consistent and reliable enclosures and control components using advanced CNC machining and sheet metal fabrication — tailored for the rigorous demands of automation panels and control cabinets.

From material traceability to final inspection, we ensure every bracket, panel, and enclosure meets stringent quality standards — so your automation systems operate safely, reliably, and in full compliance.

Discover how we helped an advanced automation manufacturer solve critical heat and EMI issues in their robot controller — without changing the enclosure footprint.

The client's compact controller chassis was overheating during high-load cycles and repeatedly failing EMC immunity testing. They required a thermally optimized, EMI-stable solution that fit their existing form factor.

Our team selected AL6063 aluminum for superior heat dissipation. We refined the heat sink fin profile through DFM and airflow analysis, then machined the enclosure on a 5-axis CNC in a single setup to maintain gasket seal alignment for EMC shielding.

The new design operated 12°C cooler at full load and passed all EMC tests on the first attempt. We also achieved a 15% reduction in unit cost thanks to optimized machining and consolidated processes.

Let our engineers evaluate your control panel or enclosure design. Receive expert insights, manufacturability recommendations, and a fast project quote — all at no cost

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam.