"Chenying's high-precision CNC shaft machining perfectly matched our robotics drivetrain needs. Their control over coaxiality and assembly fit exceeds many larger vendors."

CNC Machining -Milling & Turning

CNC machining (Computer Numerical Control) is a highly efficient and precise manufacturing process that uses computer programs to control cutting tools for shaping metals, plastics, and other engineering materials. As one of the core technologies in Shenzhen’s precision hardware manufacturing, it enables the production of tight-tolerance parts with excellent repeatability. Ideal for custom hardware components and mold fabrication, CNC machining offers a scalable solution for low-volume production and rapid prototyping.

What is CNC Machining and Why It Matters in Precision Manufacturing?

CNC machining (Computer Numerical Control) is a high-precision, high-efficiency manufacturing method that automates metalworking and plastic processing through programmable controls. Commonly applied in hardware components, plastic molds, and complex mechanical parts, it delivers consistent, tight-tolerance results while significantly enhancing production speed and repeatability.

In Shenzhen’s advanced manufacturing ecosystem, CNC technology is not just a technical process—it’s a strategic competitive edge. It supports critical industries such as aerospace, automotive, medical devices, and consumer electronics, helping companies shorten lead times, reduce costs, and improve product quality in low-volume or custom production scenarios.

Supported Materials and Machining Capabilities

Chenying provides precision CNC machining services using a full range of engineering plastics and metal alloys. Our material capabilities support everything from functional prototyping to tight-tolerance batch production. Whether you're working on plastic housings, metal frames, or custom mechanical parts, we ensure reliable machining across all materials.

Plastic Materials

| Material | Features |

|---|---|

| ABS | White / Black / Fireproof Grades |

| PC / PC+ABS | Transparent, V0 Fire Grade |

| PP / PP+GF | Glass Fiber Reinforced |

| PMMA | Acrylic – Polishable |

| PA66 / PA+GF | Reinforced Nylon |

| POM | Includes Anti-static Grades |

| PEEK / PBT / PET / PTFE / PPS | High-performance Polymers |

| PEI / PVC / Bakelite / Model Board | Engineering and Insulating Plastics |

Metal Materials

| Material | Examples / Features |

|---|---|

| Copper Alloys | Brass, Beryllium Copper, Phosphor Bronze, Zinc Alloy |

| Aluminum Alloys | 6061, 7075, 2024, 5052, ADC12, etc. |

| Steel | 45#, Alloy Steel, Spring Steel, Bearing Steel, Tool Steel |

| Stainless Steel | SS304, SS316, 17-4PH, SS303, SS410, SS630 |

All materials listed are fully compatible with our high-speed milling, CNC turning, and finishing processes. With support for low-volume orders and lead times as short as 3–5 days, our Shenzhen-based machining facility enables faster iteration and market delivery.

Machining Specifications

- Max Part Size: 500mm × 400mm × 300mm — ideal for medium-sized mechanical components

- Tolerance: ±0.01mm to ±0.02mm — supporting high-precision requirements

- Capabilities: CNC Milling, Turning, Drilling, Threading

- Surface Finishes: Anodizing, Polishing, Sandblasting, Nickel Plating

- Minimum Order: 1 piece — rapid prototyping friendly

- Lead Time: As fast as 3–5 working days for samples — ideal for time-sensitive projects

Sheet Metal & Hardware Fabrication Workflow

CAD modeling and DFM optimization ensure part strength, tolerance accuracy, and manufacturability for hardware components.

Selection of metal sheets, rods, and coils (steel, aluminum, brass) and nesting optimization to reduce waste.

Precision laser cutting or stamping shapes out parts like brackets, hinges, and enclosures with clean edges.

Using CNC press brakes and forming tools to shape parts such as clamps, frames, and covers accurately.

TIG/MIG welding, riveting, threading, and component assembly deliver strong, reliable hardware joints.

Processes include polishing, plating, powder coating, and corrosion protection for professional appearance.

Every batch passes QA inspection, tolerance verification, and is securely packaged for global shipment.

Our CNC Quality Standards and Certifications

At Chenying, an ISO 9001 certified CNC machining company, we operate under a robust quality assurance system to guarantee precision, traceability, and consistency—from raw material to final shipment.

✔ Incoming Material Inspection

All raw materials are checked for dimensions, hardness, and surface condition. Certificates are reviewed to ensure compliance before production begins.

✔ In-Process Quality Checks

During machining, operators use micrometers, calipers, and gauges to monitor critical dimensions in real-time, ensuring tight tolerance control.

✔ First Article Inspection (FAI)

For custom or first-run parts, a full FAI report is generated and approved under our ISO 9001 quality control protocol before volume production.

✔ Full Dimensional Inspection

Our QC team uses Coordinate Measuring Machines (CMM), height gauges, and 2.5D vision tools to validate all technical specifications.

✔ Surface Finish & Appearance Checks

We inspect for burr-free edges, consistent finishes, and coating quality—ensuring all parts meet visual and functional requirements.

✔ Final QC & Traceability

Each batch is documented with inspection reports, photos, and traceability logs. Full records are available upon request for audits or client validation.

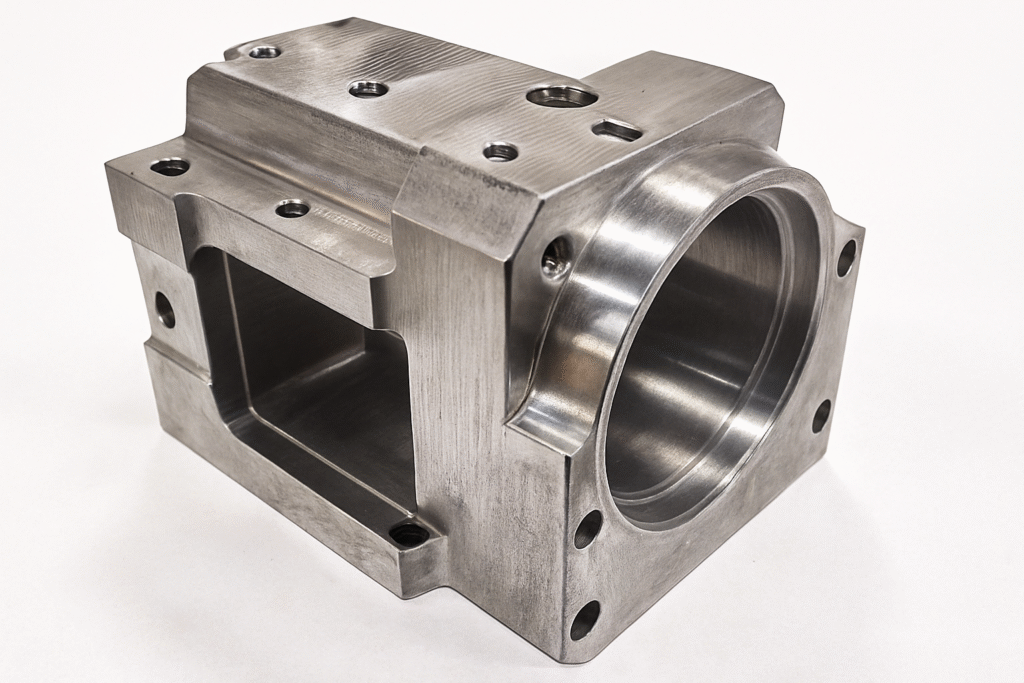

Precision CNC & Sheet Metal Part Types

-

Gear & Shaft Components

Critical for mechanical transmission and robotics. High-precision CNC machining ensures tight coaxiality and tolerance — ideal for high-load, high-speed use.

-

Housings / Enclosure Parts

Used in electronics, medical tools, and precision instruments. CNC-milled aluminum or stainless steel provides heat dissipation, strength, and anodized surface finish.

-

Precision Fixtures / Tooling

Used in automation and assembly systems. CNC machining delivers repeat positioning accuracy and structural rigidity for long-term production use.

-

Heat-Exchange / Heat-Sink Parts

Used in power, telecom, and LED systems. CNC heat sinks use high-conductivity alloys with precision surface treatment to maximize thermal performance.

-

Complex Free-Form Surface Components

Designed for aerospace and mold tooling. Multi-axis CNC machining handles freeform 3D geometry and complex surfaces with exceptional precision.

-

Small-Batch Functional Parts

Ideal for engineering validation and rapid prototyping. Supports material flexibility, design iterations, and short-run CNC production cycles.

-

Internal-Cavity Sealing Components

Designed for fluid and pneumatic sealing. CNC machining ensures dynamic tolerance control and ultra-smooth sealing surfaces.

-

Medical / Dental Custom Parts

Used in surgical guides, implants, and dental tools. CNC-machined from biocompatible plastics or titanium alloys under strict medical manufacturing protocols.

Get your customized CNC part quote—fast review and engineering feedback

Upload your STEP, IGES, or DWG files to receive a fast, custom quote for precision CNC machining. We support a wide range of materials, including aluminum alloys, stainless steel, engineering plastics, and more.

Our team provides rapid prototyping, low-volume production, and surface finishes such as anodizing and electroplating. Every submission is reviewed by an engineer to ensure manufacturing feasibility and cost optimization.

All files remain confidential. Quotes typically delivered within 1 hour during business hours.

What Our Clients Say About Chenying CNC Machining

"For titanium components in medical implants, we need ultra-tight tolerances and ISO traceability. Chenying delivers batch-consistent quality and biocompatible material control every time."

"For low-volume CNC of aluminum thermal enclosures, their speed and DFM feedback helped us improve cooling performance significantly. Excellent partner for rapid functional parts."

"We needed complex aerospace brackets with freeform 5-axis paths and post-processing. Chenying nailed the surface finish, precision, and lead time—excellent on multi-axis capability."

FAQs

What is CNC machining?

What CNC processes are commonly used?

- CNC Milling: For surfaces, slots, and 3D contours (3–5 axis).

- CNC Turning: Ideal for shafts, discs, and rotational parts.

- Drilling & Tapping: Accurate holes in housings, plates.

- EDM/Wire-cut: For hard materials or deep, narrow features.

- 5-Axis Machining: Handles complex, multi-face geometries.

Which materials can be CNC machined?

Metals: Aluminum 6061/7075, stainless 304/316, titanium, brass, carbon steel.

Plastics: POM, PEEK, PTFE, PC, ABS, PA66, PMMA.

Composites: Carbon fiber, ceramic blends, select woods (on request).

What accuracy and tolerance range can you achieve?

What are the usual lead times?

- Rapid prototypes: 1–3 business days

- Complex sets: 5–15 business days

- Mass production (100+ pcs): depends on part complexity and inspection scope

Which drawing and file formats do you support?

3D files: STEP (.stp), IGES (.igs), Parasolid, SolidWorks native.

2D files: PDF, DWG, DXF with tolerances and finish notes.