"Chenying supported our EV powertrain project with precision aluminum housing production. The parts met all tolerance specs, and prototypes were delivered in just 9 working days. Their response speed and machining accuracy are top-tier."

High-Precision Aluminum & Zinc Die Casting Services

What is die casting?

Die casting is a high-precision metal manufacturing process that injects molten non-ferrous metal such as aluminum, zinc, or magnesium into hardened steel molds under high pressure.

Key Features of Die Casting:

• High dimensional accuracy – typical tolerances up to ±0.01 mm

• Excellent surface finish – minimal post-machining required

• High-speed production – cooling and solidification completed within seconds

• Ideal for mass production – especially automotive, medical, and electronics

Compared to other forming processes, die casting offers superior repeatability, making it an ideal solution for high-volume, complex components that demand both strength and consistency.

Die Casting Materials & Capabilities

We offer a range of non-ferrous die casting alloys to meet specific application requirements — from lightweight aluminum to ultra-precise zinc. Our engineers can guide you in selecting the best alloy based on your part's design, performance, and cost priorities.

Suitable Die Casting Materials

| Material | Key Properties & Common Applications |

|---|---|

| Aluminum Alloy (ADC12 / A380) | High strength-to-weight ratio, excellent thermal conductivity Used in automotive housings, LED enclosures, drone structures |

| Zinc Alloy (Zamak 3 / Zamak 5) | Outstanding fluidity, high dimensional accuracy, excellent surface finish Ideal for decorative parts, connectors, hinges, locks |

| Magnesium Alloy (AZ91D) | Ultra-lightweight, good damping capacity, fast cooling Perfect for mobile electronics, laptop chassis, and brackets |

| Copper Alloy (Brass) | High corrosion resistance, good electrical conductivity Common in plumbing fixtures, terminals, precision fittings |

Materials Not Suitable

| Material | Why It's Not Applicable |

|---|---|

| Stainless / Carbon Steel | Melting points exceed 1500°C – die casting molds can't withstand such temperatures |

| Titanium Alloy | Highly reactive with standard molds – requires vacuum or investment casting |

| Iron | Causes tool erosion and oxidation – not suitable for high-volume production |

Selecting the right die casting alloy early leads to stronger part performance, longer mold life, and reduced manufacturing cost. Need advice? Our team is ready to support your material selection and design decisions.

Machining Specifications

- Max Part Size: 500mm x 400mm x 300mm – supports medium-sized structural parts

- Tolerance: ±0.01mm to ±0.02mm – for high-precision mechanical applications

- In-house Capabilities: CNC Milling, Turning, Drilling, Threading

- Surface Finishes Available: Anodizing, Polishing, Sandblasting, Nickel Plating

- MOQ: 1 piece – perfect for prototypes and pilot runs

- Lead Time: As fast as 3–5 working days for samples – suited for time-critical projects

Die Casting Manufacturing Workflow

Mold is mounted and clamped securely, preheated to optimal working temperature. Release agent is applied to ensure smooth part ejection and protect the die.

Aluminum, zinc, or magnesium alloy is melted in a controlled furnace. Impurities are skimmed to maintain metal purity for consistent casting quality.

Molten metal is injected at high speed into the die using cold or hot chamber machines — ensuring rapid and full cavity fill with minimal porosity.

Die temperature is precisely managed for fast solidification and optimal microstructure — improving mechanical strength and dimensional accuracy.

Once solidified, the die opens and ejector pins push the part out. Robotic arms or manual pickers handle the parts safely to prevent damage.

Excess material (gates, runners, flash) is trimmed using hydraulic presses or manual tools. Secondary deburring ensures clean part edges.

CNC machining, surface finishing (anodizing, plating), and quality checks (X-ray, CMM inspection) are performed before shipment.

Die Casting Post-Processing & Quality Assurance

From raw casting to ready-to-ship components, Chenying provides full-cycle manufacturing including die casting, CNC machining, surface finishing, and assembly. Our value-added post-processing ensures functional reliability and cosmetic excellence — ready for final installation or resale.

✔ Precision CNC Machining

Over 50 in-house CNC machines perform drilling, milling, and threading with micron-level precision — optimized for aluminum and zinc die-cast parts.

✔ Welding & Structural Integration

Robotic and laser welding support integration with sheet metal frames, brackets, and module assemblies, delivering seamless mechanical fit.

✔ Durable Surface Finishing

Automated powder coating, spray painting, and chromate pre-treatment enhance corrosion resistance, wear life, and aesthetic quality.

✔ Standardized QA System

Visual checks, dimensional measurements, and X-ray inspections are conducted under standardized protocols for batch-to-batch consistency.

✔ Tight Tolerance Fitment

Perfect alignment for enclosures and mating parts — essential for industrial electronics, sensors, and high-load assemblies.

✔ Faster Time-to-Market

Integrated production shortens supply chains and protects your IP — enabling confidential development and faster delivery.

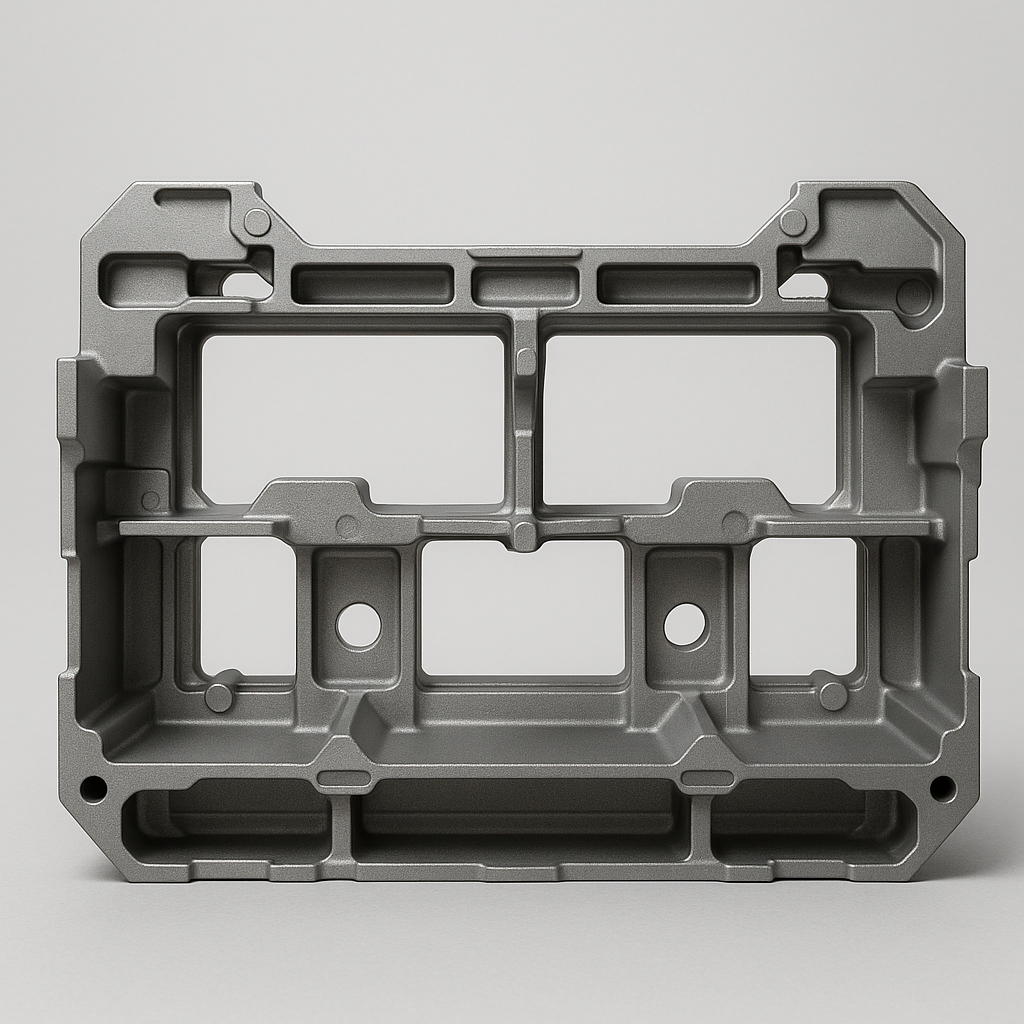

Die-Cast Part Types & Applications

-

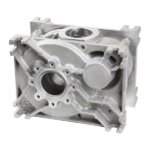

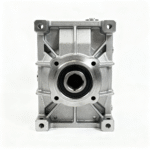

Engine & Transmission Housings

High-strength enclosures with tight sealing requirements. Commonly used in automotive, electric vehicle, and industrial gearbox systems.

-

Heat Sink & Thermal Modules

Die-cast fins and bases designed for rapid heat dissipation in power electronics, LED lighting, EV chargers, and telecom devices.

-

Communication Control Enclosures

Aluminum enclosures with EMI shielding, waterproof sealing and corrosion resistance for 5G base stations and smart network hubs.

-

Automotive Structural Components

Die-cast brackets, pedals and crash energy absorbers. Lightweight and robust — ideal for modern vehicle platform architectures.

-

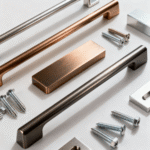

Decorative Hardware & Home Appliance Parts

Polished zinc alloy parts with complex shapes and tight tolerances. Suitable for consumer products requiring visual quality.

-

Consumer Electronics Casings

Ultra-thin magnesium or aluminum housings for laptops, tablets, and IoT devices — combining sleek design with EMI protection.

-

Valve Bodies & Plumbing Components

Pressure-sealed components made from brass or zinc alloys. Reliable for liquid control, household plumbing, and fluid systems.

Get Your Die-Cast Parts Quote—Quick Review and Engineering Feedback

Upload your STEP, IGES, or DWG files to receive a fast, custom quote for high-quality die casting services. We support a wide range of materials including aluminum alloys, zinc alloys, and magnesium alloys.

Our team specializes in rapid tooling, low-to-medium volume production, and secondary operations such as CNC machining, surface finishing, and assembly. Every submission is reviewed by a die casting engineer to ensure part feasibility, mold design optimization, and cost efficiency.

All files remain strictly confidential. Quotes are typically delivered within 1 hour during business hours.

What Our Clients Say About Chenying Die Casting

"We struggled with inconsistent finishing from previous vendors. Since switching to Chenying, their automated powder coating line has delivered flawless finish and strong paint adhesion. They're very responsive and professional in project handling."

"We've been working with Chenying for over 3 years for custom die-cast enclosures with CNC finishing. Their vertical integration saves us weeks in supplier coordination. They always ship on time — we trust them fully."

"As a startup, we needed flexible vendors for low-volume magnesium die-casting. Chenying helped from early DFM to post-processing. They're agile, reliable, and understand how to support fast product iteration."

FAQs

Which materials are supported for die casting?

What is the typical mold lifespan?

- Aluminum die casting molds: 80,000–120,000 cycles

- Zinc die casting molds: up to 1 million cycles