1 Carbon Steel

- FormsSPCC, Q235

- FeaturesHigh strength, easy to weld, cost-effective

- ApplicationsCabinets, support brackets, chassis

- SurfacePowder-coated, galvanized

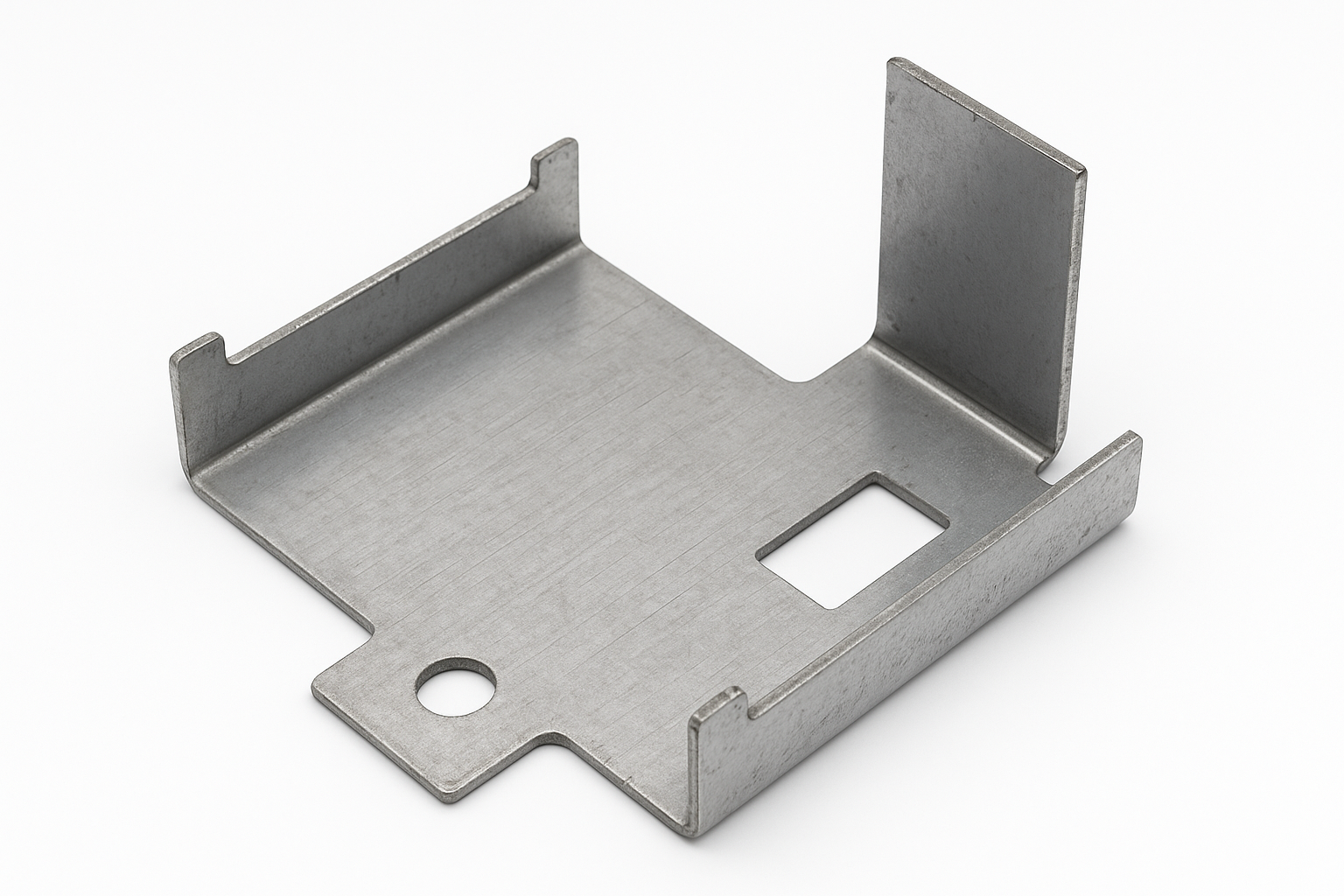

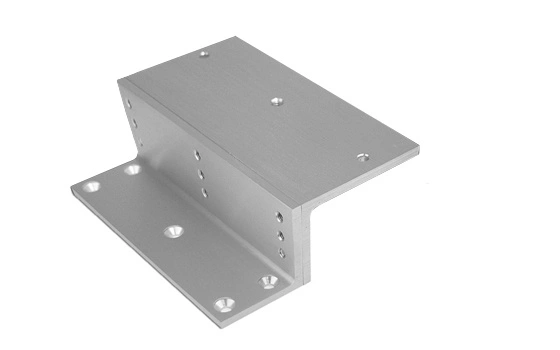

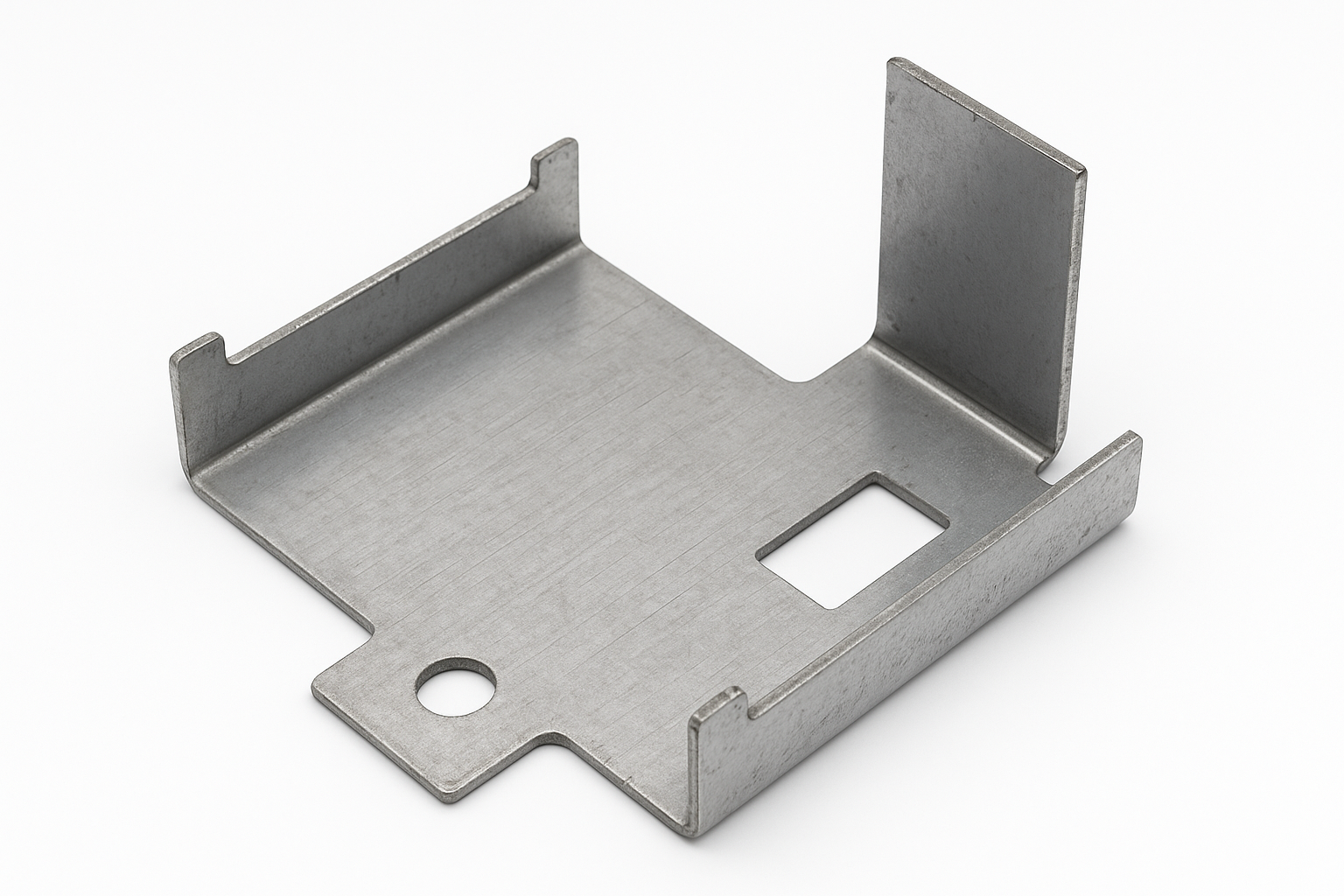

Our sheet metal fabrication services deliver high-precision parts through laser cutting, bending, welding, and assembly. We work with aluminum, steel, stainless steel, and other materials to produce durable enclosures, brackets, and structural components. Whether you need rapid prototypes or full production runs, our ISO-certified processes ensure consistent quality and fast turnaround. Upload your design to get an instant quote and start your custom sheet metal project today.

Sheet metal fabrication is a multi-step manufacturing process that transforms flat metal sheets into functional parts through techniques such as laser cutting, blanking, bending, stamping, welding, riveting, and surface finishing. These methods allow for the production of enclosures, brackets, panels, and other custom components with high dimensional accuracy.

This process is essential across industries like automotive, electronics, telecommunications, construction, and home appliances. Its versatility and scalability make sheet metal fabrication a core capability in modern industrial manufacturing, supporting everything from low-volume prototypes to high-volume production.

Explore material options like aluminum, stainless steel, galvanized steel and more — each with distinct properties for strength, corrosion resistance, and appearance.

| Material | Ideal For | Not Recommended When |

|---|---|---|

| Carbon Steel | Low-cost structural parts | Outdoor or wet environments |

| Stainless Steel | Hygienic, corrosion-resistant parts | Ultra-lightweight needs |

| Aluminum | Lightweight parts with moderate strength | High structural load-bearing |

| Copper | Electrical conduction and aesthetics | Mechanical loads or harsh environments |

| Galvanized | Rust protection in general outdoor use | High-temperature conditions |

Not sure which material is best for your custom sheet metal part? Request expert material selection help →

We prepare 2D/3D files and generate accurate toolpaths to ensure production feasibility and tight tolerances.

High-precision CO₂ or fiber laser cuts and CNC punching create clean, burr-free edges with optimized nesting.

Hydraulic press brakes shape metal parts with precise angles and repeatability, even for complex geometries.

We offer TIG, MIG, spot welding, and hardware insertion to ensure structural strength and integration of components.

Powder coating, plating, brushing, or anodizing improves corrosion resistance and enhances visual appeal.

Every part undergoes dimensional checks and cosmetic inspections before careful packaging and delivery.

With 60+ machines including laser cutters, CNC punch, press brakes, robotic welders, and automated powder coating lines, we deliver high-volume and custom sheet metal parts with unmatched consistency.

All fabrication—from CAD review, cutting, welding to finishing—is performed under one roof at our ISO‑certified Shenzhen plant. This ensures tighter control, faster delivery, and lower costs.

We meet ISO 9001:2015 standards with full QC documentation: FAI, PPAP, SPC reports, RoHS material traceability, and visual/cosmetic inspection for export compliance.

Whether it's a telecom bracket, medical housing, or automotive panel, our engineers tailor DFM solutions to your specific part geometry and production volume—no templates, just precision.

Upload your drawings and receive a quote within 12–24 hours. Bilingual engineers ensure every communication is fast, clear, and technically accurate across time zones.

Chenying is a long-term OEM sheet metal supplier for clients across Europe, North America, and Asia, with a proven record of lean production, just-in-time delivery, and zero-defect mentality.

Want to verify if we're the right fabrication partner for your part?

Contact Chenying for a free DFM review →

Laser-cut, powder-coated steel or aluminum cabinets for telecom, server, and electrical control systems with vent holes and lockable panels.

Precision-bent steel or stainless brackets for PCB holders, screens, or machine mounting—available with countersinks and inserts.

Customized protective shields for motors, sensors, or electronics. Made in aluminum or galvanized steel with anti-corrosion finish.

Formed and riveted ducts for HVAC or electronic airflow, with perforated or louvered faceplates, finished in matte black or anodized.

Stamped and spot-welded inner fender panels, brackets, and reinforcements for EV, truck, or heavy-duty vehicle manufacturers.

Laser-cut signage, aluminum facade panels, and interior trims with brushed, mirror, or anodized surface finish options.

Looking for a custom version of these parts?

Request a Quote from Chenying Hardware →

Upload your STEP, IGES, DWG, or PDF files and get a precise quote within 1 hour during business hours. We offer laser cutting, CNC bending, welding, and surface finishing in stainless steel, aluminum, copper, and more.

Our first order was a CNC-cut enclosure for an electrical cabinet. From CAD confirmation to finished sample, Chenying Hardware delivered in just 3 days. Everything was dimensionally accurate and powder-coated to spec—extremely efficient and professional.

Our parts had complex bends and tight hole locations. Chenying's engineers proactively suggested DFM changes that saved us from costly mistakes. The first prototype passed assembly perfectly. Outstanding technical support.

We've ordered over 10 batches of sheet metal housings. Chenying Hardware delivers on time with high consistency and quality. They are a dependable vendor for both prototype and production runs.

We submitted only 3D STEP files without flat layouts. Chenying's team created proper developments and flagged fitment issues early. Their in-house engineering capability is a big plus for design-stage collaboration.

Our aluminum enclosures needed sandblasting and anodizing with strict color tolerances. Chenying provided finish samples and adjusted perfectly to our target. The final result impressed both us and our end customer.

One delivery had minor surface marks. Chenying handled the issue immediately—replaced the units and took full ownership. They're not just a vendor, they're a responsible partner.

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam.